Automotive – Racing – Nautica

Aerospaziale e Difesa

Galvanica

Chimica e Petrolchimica

Meccanica di precisione

Automotive – Racing – Nautica

Soluzioni tecnologicamente avanzate che uniscono ricerca e prestazioni di livello per l’ottenimento di performance di eccellenza.

Aerospaziale e Difesa

Massima garanzia della qualità dei prodotti attestata da report di laboratori.

Cheese head screws with internal serration

-

Standard Parts / Description Material

-

LN 29950 / Aerospace Cheese head screw with internal serration, titanium alloy - 1100 MPa 3.7164.7

-

DIN 65540 / Aerospace Cheese head bolt with internal serration, MJ thread, reduced shank, titanium alloy for temperatures up to 315 °C - 1100 MPa 3.7164.7

-

DIN 65517 / Aerospace Cheese head bolt with internal serration, close tolerance, MJ thread, short thread, titanium alloy for temperatures up to 315°C - 1100 Mpa 3.7164.7

-

DIN 65515 / Aerospace Cheese head bolt with internal serration, MJ thread, short thread, titanium alloy for temperatures up to 315 °C - 1100 MPa 3.7164.7

-

LN 29949 /Aerospace Cheese head screw with internal serration, corrosion resisting steel, for temperatures up to 650 °C - 1100 MPa 1.4944.6

Six Lobe Recess bolts

-

Standard Parts / Description Material

-

DIN EN ISO 14579 / Hexalobular socket head cap screw - depending on material and thread sizea A2/50/70 A4/50/70

-

DIN EN ISO 14580 / Hexalobular socket cheese head screw – depending on material and thread size A2/50/70 A4/50/70

-

DIN EN ISO 14581 / Hexalobular socket countersunk flat head – depending on material and thread size A2/50/70 A4/50/70

-

DIN EN ISO 14583 / Hexalobular socket pan head screw – depending on material and thread size A2/50/70 A4/50/70

-

ASN A0090 / Pan head screw with six lobe recess, ISO M thread – see NFL bolts / see NFL bolts A2/50/70 A4/50/70 3.7164.7

Pan Head and Countersunk Bolts

-

Standard Parts / Description Material

-

DIN EN 4178 / Aerospace Pan head, six lobe recess, coarse tolerance normal shank, medium length thread, titanium, anodized, MoS2 - 1100 Mpa 3.7164.7

-

LN 9139 / Aerospace Round head screw, cross-recessed, non-magnetizable - 700 Mpa 1.4541 A2-70

-

LN 9441 / Aerospace Countersunk head screw, cross-recessed, titanium alloy - 1100 Mpa 3.7164.7

-

LN 9442 / Aerospace Pan head screw, cross-recessed, titanium alloy - 1100 Mpa 3.7164.7

-

LN 29958 / Aerospace Pan head screw with internal offset cruciform ribbed drive recess, titanium alloy, threaded to head - 1100 Mpa 3.7164.7

-

DIN EN 3759 / Aerospace pan head screws, offset cruciform recess, threaded to head, heat and corrosion resisting steel, passivated - 1100 Mpa 1.4944.6

-

DIN EN 3760 / Aerospace 100° countersunk normal head, offset cruciform recess, threaded to head, heat and corrosion resisting steel, passivated - 1100 Mpa 1.4944.6

-

DIN 65324 / Aerospace Pan head screw, close tolerance, with internal offset cruciform ribbed drive recess, titanium alloy, short length MJ-thread, for temperatures up to 315 °C - 1100 Mpa 3.7164.7

-

DIN 65179 / Aerospace Countersunk head screw, close tolerance, with internal offset cruciform ribbed drive recess, titanium alloy, short length MJthread, for temperatures up to 315°C - 1100 Mpa 3.7164.7

-

DIN 65316 / Aerospace Countersunk head screw, close tolerance, with internal offset cruciform ribbed drive recess, corrosion-resisting steel, short length MJ-thread, for temperatures up to 425°C - 1100 Mpa 1.4944.6

-

LN 9136 / Aerospace Countersunk head screw, cross-recessed, non-magnetizable - 700 Mpa 1.4541 A2-70

-

DIN EN 3037 / Aerospace Pan head, offset cruciform recess, close tolerance normal shank, short thread, titanium, anodized, MoS2 - 1100 Mpa 3.7164.7

-

DIN EN 3038 / Aerospace Pan head, offset cruciform recess, close tol. Normal shank, short thread, corrosion resistant steel, passivated - 1100 Mpa 1.4944.6

-

DIN EN 3304 / Aerospace Countersunk reduced head, offset cruciform recess, close tolerance, short thread, titanium, anodized, MoS2 - 1100 Mpa 3.7164.7

Hexagon and Double Hexagon Bolts

-

Standard Parts / Description Material

-

DIN 65265 / Aerospace Hexagon screw with MJ-thread, titanium alloy, threaded approximately to head for temperatures up to 315 °C - 1100 Mpa 3.7164.7

-

DIN 65522 / Aerospace Hexagon screw with MJ-thread, corrosion-resisting steel, threaded approximately to head for temperatures up to 425 °C - 700 Mpa 1.4541 A2-70

-

DIN EN ISO 4762 ( DIN 912 ) / Hexagon socket head cap screw, steel, corrosion-resisting steel, nonferrous metall - depending on material and thread size A2/50/70 A4/50/70 3.7164.7 1.4944.6

-

DIN EN ISO 10642 ( DIN 7991) (UNI 5933) / Hexagon socket countersunk head screw, steel, corrosion-resisting steel, nonferrous metall - depending on material and thread size A2/50/70 A4/50/70 3.7164.7

-

DIN 65338 / Hexagon bolts, close tolerance, with short-length MJ thread, shoulder, titanium alloy, nominal tensile strength 1 100 MPa, for temperatures up to 315 °C; 3.7164.7

-

DIN 65339 / Hexagon bolts, close tolerance, with short-length MJ thread, corrosion-resisting steel - Nominal tensile strength 1100 MPa, for temperatures up to 425 °C 1.4944.6

-

LN 65056 / Aerospace Double hexagon head bolt, close tolerance, from titanium alloy, medium thread length - 1100 Mpa 3.7164.7

-

LN 29902 / Aerospace Double hexagon screw, close tolerance, heat-resisting steel, for temperatures up to 650°C - 900 Mpa 1.4944.4

-

LN 29551 / Aerospace Double hexagon screw, corrosion-resisting steel for temperatures up to 650°C - 900 Mpa 1.4944.4

-

NFL 22-232 / Bihexagonal bolt with locking hole, ISO M thread, 4h class - depending on code letter (material) 3.7164.7 1.4944.4 1.4944.6

-

NFL 22-237 / Bihexagonal bolt with locking hole, ISO M thread, 4g class - depending on code letter (material) 3.7164.7 1.4944.4 1.4944.6

Torq-set screws

-

Standard Parts / Description Material

-

LN 29787 / Aerospace Countersunk head screw with torq-set recess, fully threaded to head, titanium alloy - 1100 Mpa 3.7164.7

-

LN 29974 / Screws, countersunk head TORQ-SET recess Nearly threaded to the head 3.7164.7

Nuts

-

Standard Parts / Description Material

-

DIN 65281 / Nuts, hexagon, thin, with MJ thread, corrosion-resisting steel, classification: 1100 MPa/315 °C/425 °C 1.4944

-

LN 9338 / Aerospace - Hexagon washer nuts, self-locking, for temperatures up to 235 °C 1.4944 A2/50/70 A4/50/70 3.7164.7

Washers

-

Standard Parts / Description Material

-

LN 9025 / Aerospace Washer 1.4944

-

LN 9016 / Aerospace Washer, bevelled 1.4944

-

DIN 65209 / Washers, countersunk 1.4944

Nuts

-

Standard Parts / Description Material

-

DIN 65281 / Nuts, hexagon, thin, with MJ thread, corrosion-resisting steel, classification: 1100 MPa/315 °C/425 °C 1.4944.6

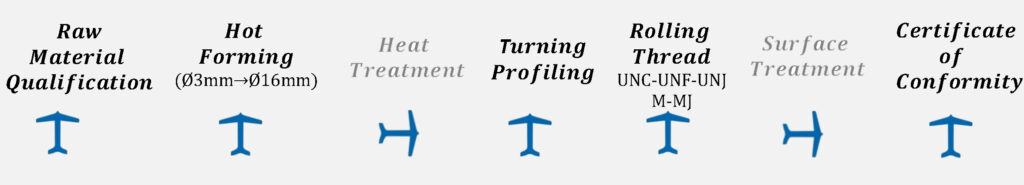

Manufacturing Technologies and Acceptance Requirements for Fasteners

-

Acceptance Requirements to Technical Specification

-

DIN 65058/AIR 9173/NAS 4003 for corrosion-resisting steel, strength class 900 MPa and 1100 MPa (1.4944.4 / 1.4944.6)

-

DIN ISO 9152/DIN 65251/AIR9185/ISO 8168/NAS 4004 for titanium alloy, strength class 1100 MPa (3.7164.7)

-

DIN 65251/AIR 9184/AIR 9185 NAS 4004 for titanium alloy, strength class 900 MPa and 1100 MPa (3.7164.1 / 3.7164.7)

-

ECSS-E-HB-32-23A / Space engineering Threaded fasteners handbook

-

ECSS-Q-ST-70-46C Rev1 / Space product assurance, requirements for manufacturing and procurement of threaded fasteners

-

Manufacturing and Testing Requirements

-

The head of the bolts is forged in such a way that the grain of the material remains unchanged and that the longitudinal continuity of the fibers remains unchanged even in the critical transition area between head and stem, thanks to the control of the molding temperatures

-

The thread is cold rolled to obtain a significant increase in resistance thanks to cold plastic deformation, excellent roughness values on the thread sides and on the lower radius, no interruption of the direction of the fibers as occurs in cut threads and reduced sensitivity to notch

-

Microstructure examinations of the head to shank and the thread grain flow, the fillet work effect, as well as the grain structure and grain size of the finished part

-

Tensile Tests - Double Shear Test - Tension Fatigue Tests

-

Hardness tests according to Vickers or Rockwell

-

Magnetic or Dye Penetration testing to check surface discontinuities by aerospace qualified people l

Galvanica

L’utilizzo di minuteria in titanio in ambito galvanico assicura una lunga durata nel tempo di componenti essenziali per le esigenze del settore.

Chimica e Petrolchimica

Resistenza alla corrosione, alto rapporto resistenza/peso, conducibilità elettrica :

caratteristiche a cui rispondono pienamente le minuterie proposte da LLS TITANIUM per questi settori.

Meccanica di precisione

Ricerca di prestazioni sempre più performanti in risposta alle varie esigenze dei singoli clienti.